Reliant RM Quality Control & Assurance Management App

How it works

Ensuring consistent product and service quality requires a structured approach to inspections, compliance tracking, corrective actions, and continuous improvement. A strong quality control and assurance system minimizes defects, enhances customer trust, and ensures regulatory compliance.

Identify the types of records you need to manage

A quality control and assurance program depends on meticulous record keeping to track inspections, compliance efforts, and corrective actions. Reliant RM includes:

Quality Inspection Reports

Compliance Tracking Logs

Process Optimization Reports

CAPA Logs

Supplier Quality Management Records

Training & Development Records

Continuous Improvement Documentation

Document Management & Version Control

Put your framework in place

Organizations must align their quality control programs with regulatory and industry standards to ensure compliance and product consistency. Reliant provides a regulatory library depending on your industry, so you may structure your program around:

ISO 9001

ISO 13485

ISO 22000

HACCP

IATF 16949

GMP

FDA, EPA, and other industry specific regulations

Custom frameworks

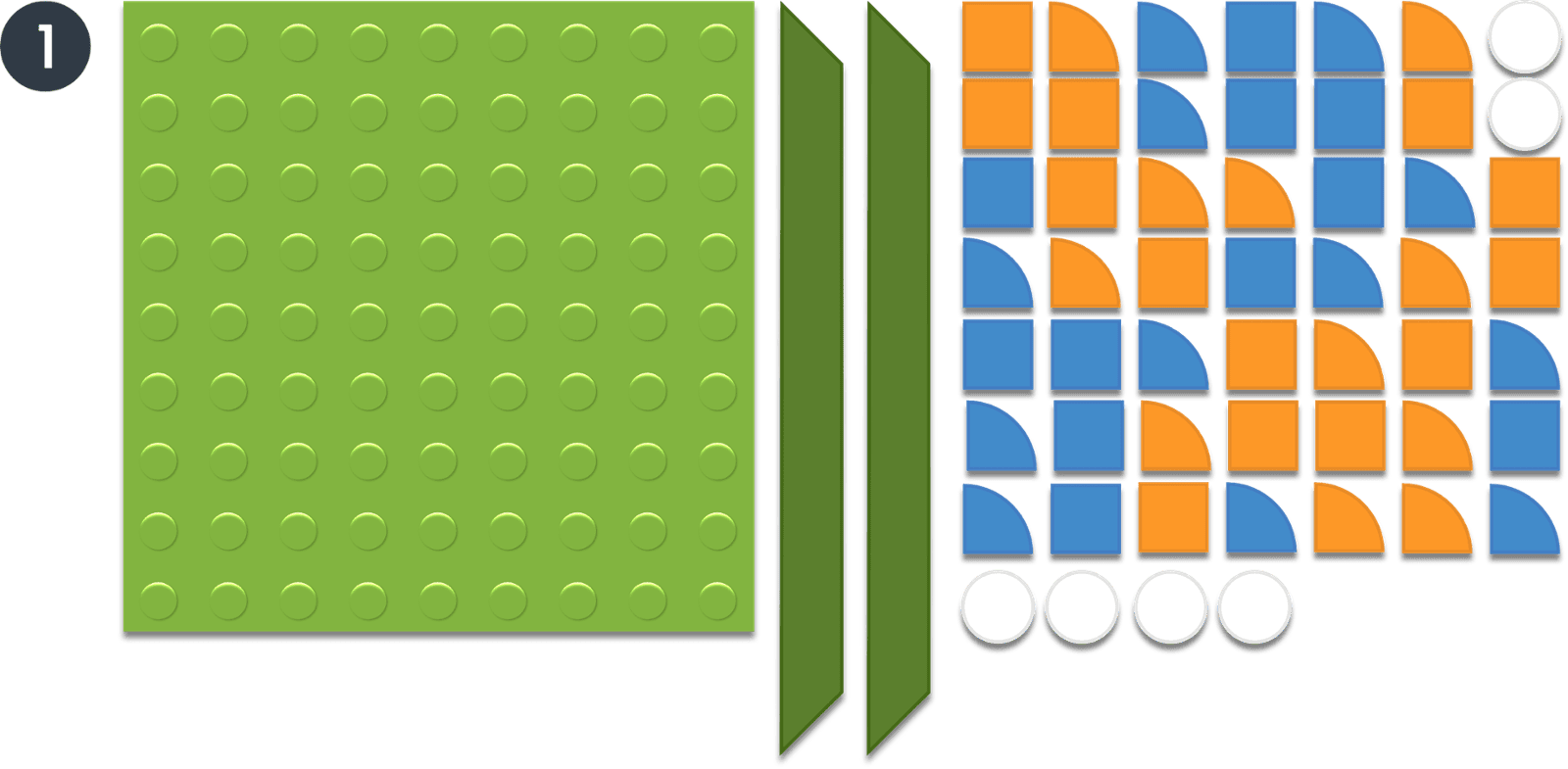

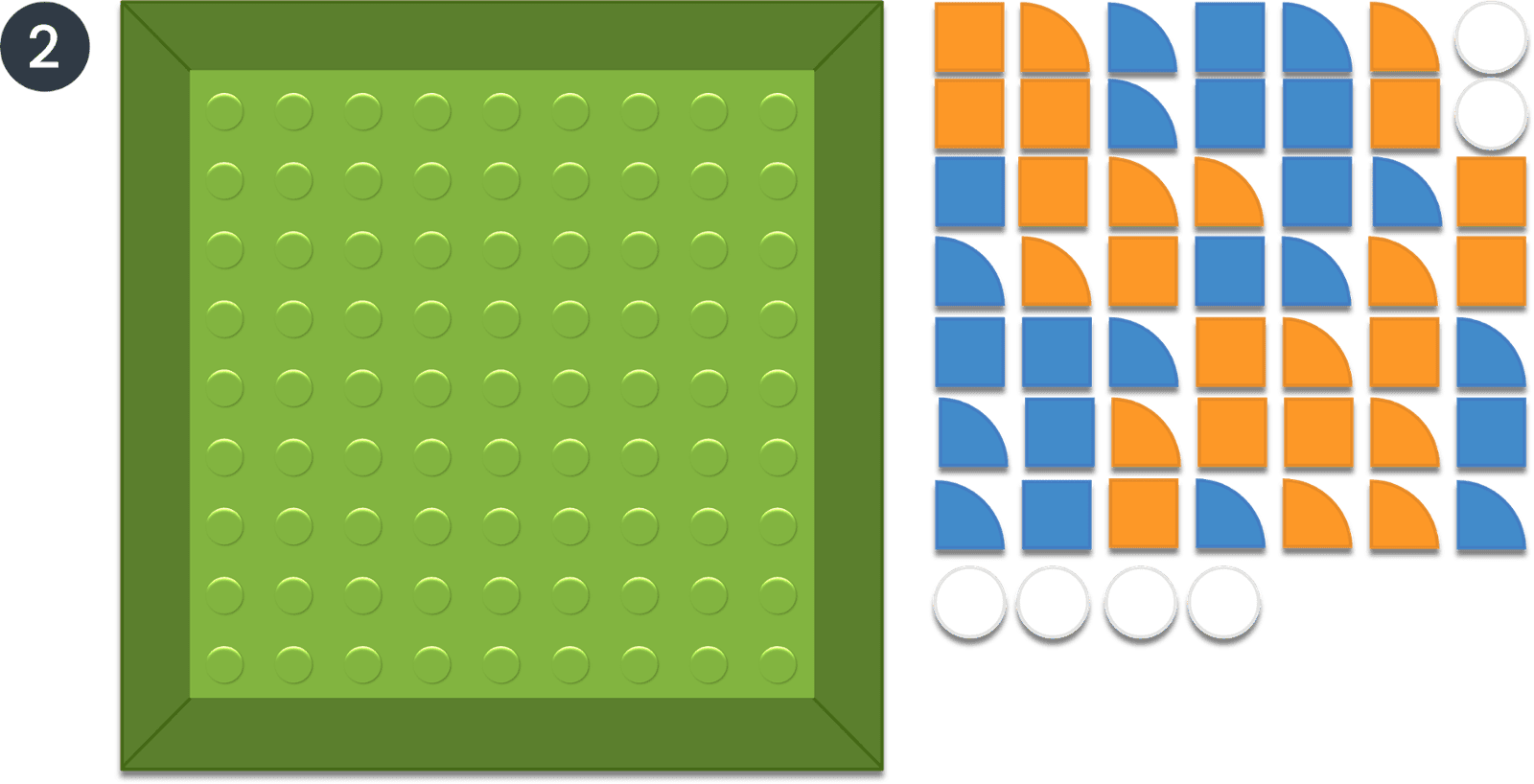

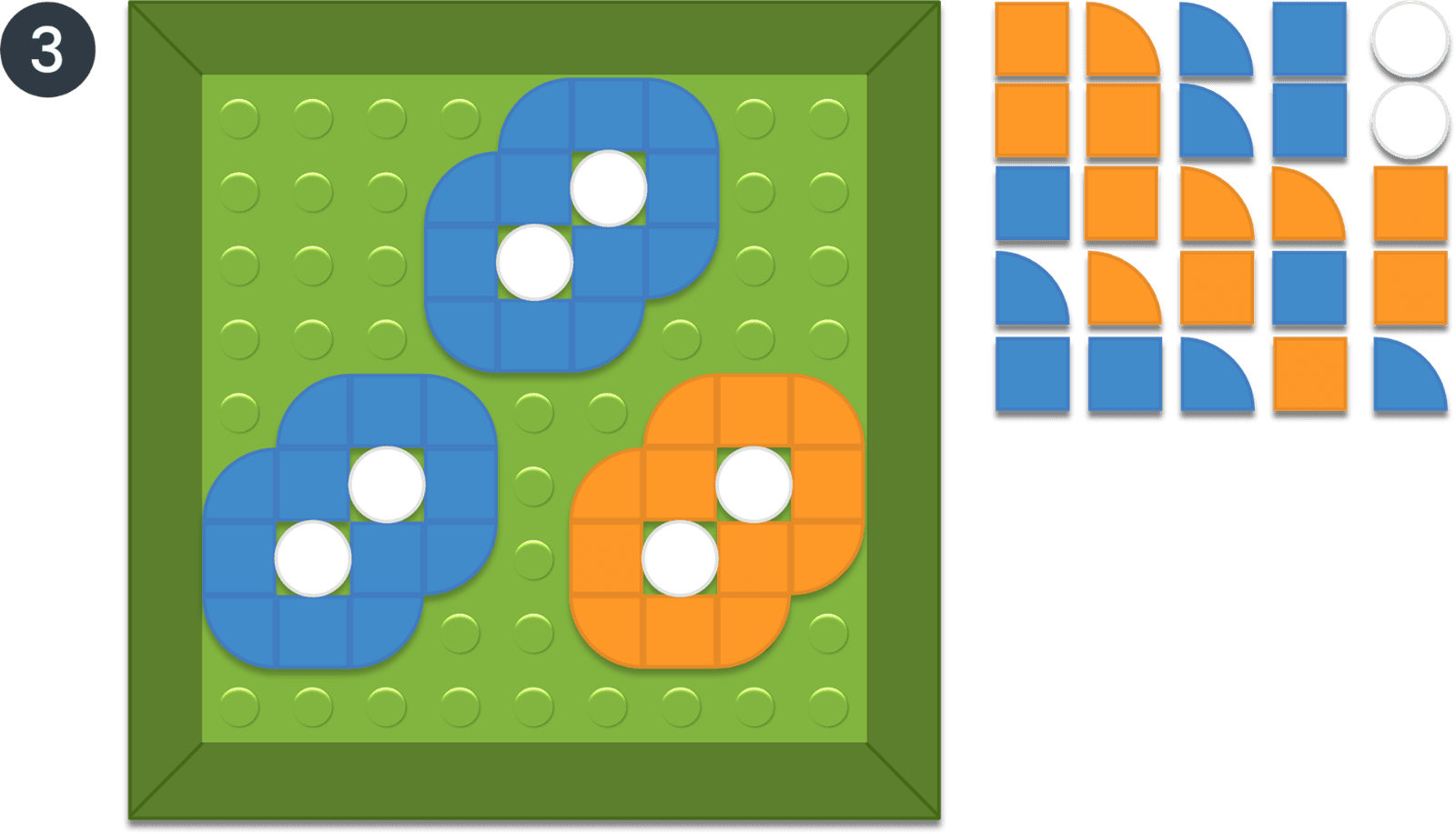

Design custom forms & workflows

Now it's time to design how your program will operate. Reliant provides all the tools you need to:

- Create custom forms and quality control logs – Build digital forms to standardize inspection protocols for products and processes, structure documentation for corrective and preventive actions, assess vendor compliance with quality requirements, track employee competency and skills development.

- Develop workflows for quality assurance – Automate processes like inspection & defect tracking, CAPA Management, compliance monitoring, and supplier quality management.

- Utilize dynamic reporting & analytics dashboards – Monitor defect rates, supplier performance, audit outcomes, and training compliance in real-time. Generate custom reports to identify trends, process inefficiencies, and quality improvement areas.

Plan for future adaptation

& scalability

A quality management system must evolve with regulatory updates, process improvements, and business growth. To future-proof your program Reliant allows organizations to:

Ensure Scalability for Expanding Operations – Adapt the system to support multi-site manufacturing, new product lines, and evolving supplier networks.

Integrate Supplier Quality & Performance Tracking – Monitor supplier compliance, quality trends, and potential risks in real time.

Enable Continuous Process Improvement –Use feedback loops and CAPA tracking to refine manufacturing and operational processes.

Connect Quality Assurance with Compliance & Risk Management Systems – Integrate with environmental, safety, and regulatory compliance tools for holistic quality management.